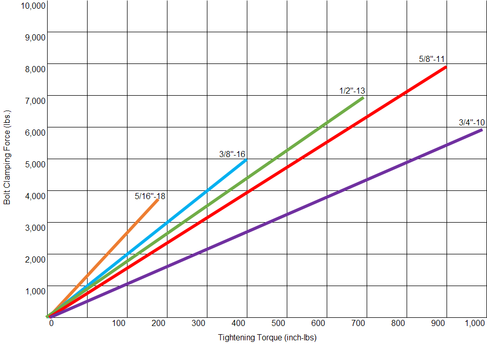

Suggested Tightening Torque Values to Produce Corresponding Bolt Clamping Loads

- Tightening torque values are calculated from the formula T = KDP, where T= tightening torque. lb-in. K=torque-friction coefficient; D = nominal bolt diameter. in; and P = bolt clamp load developed by tightening. lb.

- Clamp load is also known as preload or initial load in tension on bolt. Clamp load (lb) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load(psi) times tensile stress area(sq in.) of threaded section of each bolt size. Higher or lower values of clamp load can be used depending on the application requirements and the judgement of the designer.

- Tensile strength (min psi) of all Grade 7 bolts is 133,000. Proof load is 105,000 psi.

- Tensile strength (min psi) of all Grade 8 bolts is 150,000 psi. Proof load is 120,000 psi. Ref.:Fastening Reference, Machine Design, Nov 1977.