Our Spring Discs Keep Flanges Secure Against Unexpected Loads.

Spring Discs Resist Looseness Due to Thermal Expansion and Contraction.

Spring Discs Resist Looseness Due to Thermal Expansion and Contraction.

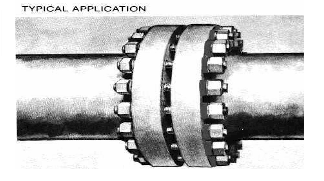

Live Loading with Fan Disc Flange Washers

It is estimated that 50% to 80% of all flange leaks are caused by insufficient bolt preload. Typically, the bolts are all tightened to a given aim preload. At this original load the bolt has a certain amount of stretch and the gasket yields (takes a set). At start-up, the process fluid heats up the flange and gasket causing them to expand more than the bolts. This leads to an increase in gasket stress causing more yielding. As the bolt temperature rises, preload may fall substantially. This is because the bolt stretch is insufficient to "make up-'for what is lost when the gasket yields. For example, if the bolt stretch was .005" and the gasket yield is .005", then all of the original preload will be lost. Fan Disc Flange Washers are effective because they add deflection to the fastening system. This is known as "Live Loading". Flange washers are Belleville springs that are typically very elastic compared to the bolts they are used with. The increase in elasticity leads to dramatically less loss of preload when joint components yield. Using the previous example, if the joint employed two flange washers with .025" of deflection each, then preload would fall by only 9% rather than 100%. Examples of candidates for live loading using flange washers are: A. Flanges where failure could cause a safety problem. B. Joints that see large temperature fluctuations. C. The length to diameter ratio of the bolt is less than three. D. One or more of the flange components are subject to yielding such as gasket creep, bolt creep, vibration, or elastic interaction. E. The flange has a history of maintenance problems. Live loading will not correct all flange leaks. However, maintaining more of the original preload will significantly reduce the risk of failure. It has been shown through various studies by a number of petrochemical companies, that the use of flange washers has a positive overall impact on the performance of a live loaded flange joint. Selecting a material

The obvious selection would be to use the same material used for the bolt. However, since Bellevilles are normally made from materials which make good springs, this is not always possible. Fan Disc Corporation produces flange washers in three different materials. H-13 Tool Steel, 17-7PH Stainless Steel and Inconel 750 Nickel Alloy. The material you select should be based on the design and environment of the flange joint being live loaded. The description and characteristic of each of these steels can be found in the catalog pages of our technical catalog. |

Selecting the right size

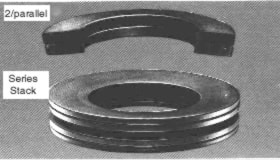

Fan Disc's flange washers are designed so that the OD of the spring matches the points on a standard nut. This is done to prevent any interference between the flange washer and the flange and so the spring will not overhang the flange joint. Next the flat load of the flange washer must be selected. Ideally, the flat load should equal the calculated preload based on the gasket design and criteria. In other words, the preload calculations should not be any different than when no flange washers are used. Multiple washers can be stacked in parallel to achieve varying flat loads. The calculated preload may not always equal the flat load of a single spring. If this is the case choose the spring with the flat load closest to the aim preload. The flange washer will not be damaged if the flat load is exceeded. On the contrary, completely flattening the Belleville optimizes it's benefit. There are applications where flange washers should not be completely flattened, such as cyclical and when flange washers are employed to reduce the increase in preload that occurs during a temperature cycle by using a Belleville with a flat load that is higher than the assembly preload. Contact Fan Disc for more information. How many flange washers per bolt? A good rule of thumb is to use two: one on each end of the bolt. This will increase the deflection of the fastening system by a factor of 7 to 15 for atypical 3001b flange joint. This increase should be ample for almost any bolting application. Excessive movement in joint materials, short active bolt length, and high differential thermal expansion are some examples where more than two flange washers should be used. Fan Disc's engineering staff can assist you when these problems occur. Material: STAINLESS: 17/7 PH (Armco) precipitation hardened Hardness: Rc-38-43 TEMPERATURE RANGE: -220 C to +300 C For higher temperatures, to +600 C we can supply Inconel X-750 (non standard) Note: For normal operating temperatures, we can supply Chrome Vanadium SAI 6150.

Tolerance: OD - Plus .000/Minus 1.5% x OD (designed for standard Flange spot face diameter) (D-Minus .000/Plus/Minus 1.5% ID THICKNESS - Plus/Minus 5% x normal thickness shown LOAD - Plus/Minus 20% of nominal shown (when ordering, ALWAYS specify materials after part number) |