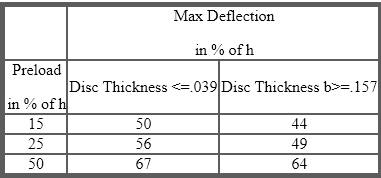

Dynamic LoadingDynamic loading of disc springs occurs when the load continuously changes from preload to final load.

The "stress-time" curve of such disc springs which pulsate uniformly is sinusoidal. This is not true in cases of impact loading and therefore it is difficult to predict their life and behavior. Disc spring "life" may be differentiated into 2 categories:

|

Fatigue LifeFatigue life for a disc spring is defined by the effective number of stress cycles that can be sustained prior to failure under certain conditions. This depends on the minimum stress, maximum stress and stress range.

The diagrams presented here are for evaluating fatigue life of single disc springs or series stacks not more than 6 springs. There are three basic groups, depending on thickness (see legend under each diagram). The horizontal border line enclosing the top portion of the graph (zone) represents the yield strength of the spring steel material. Intersection points of min/max stress limits which fall outside the graph/zone boundaries are to be avoided as they indicate spring failure is likely at an early stage. |

|